- AUTOMATION

- SUB-STATION

- COMMUNICATION

- AIR INTAKE FILTER

- CABLE

- BUILDING MANAGEMENT SYSTEM(BMS)

- GENSET ENGINE

- SOLAR SYSTEM

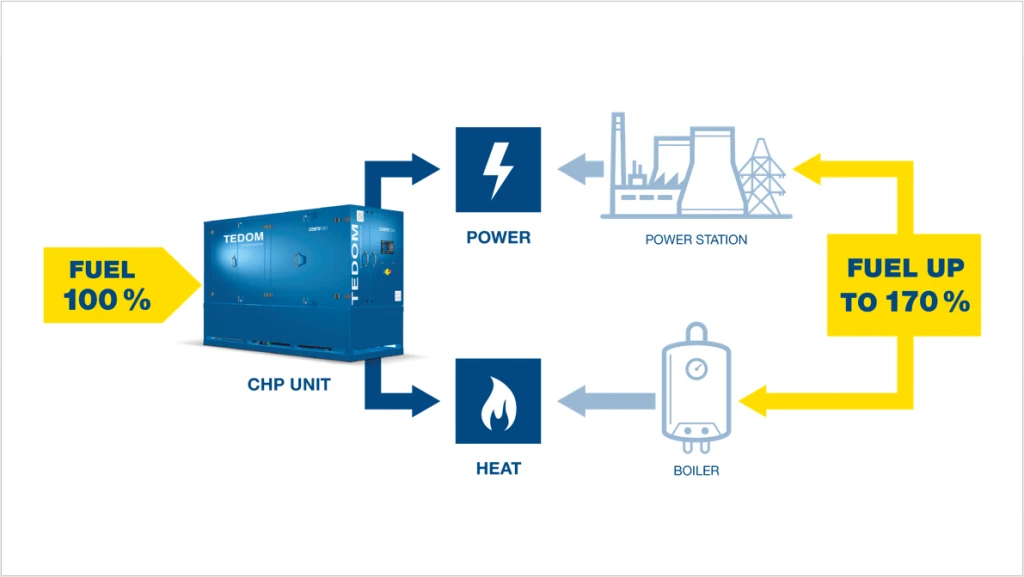

A cogeneration system (also called a Combined Heat and Power system, or CHP), can deliver significant benefits for commercial and industrial (C&I) customers, because it produces heat and electricity at the same time. Using the same fuel to generate both heat and electricity therefore improves plant’s /energy energy efficiency, delivers environmental benefits and ensures savings. Cogeneration power plants generally operate at between 50 to 70% higher efficiency rates than traditional power plants. The European Union has incorporated cogeneration into its energy policy aimed at reducing greenhouse gases and becoming carbon neutral by 2050.

The process of cogeneration produces heat and power, however during the summer months the heat generated may not be fully utilised on site. Trigeneration is a combination of cogeneration and absorption chilling – by using the excess heat to operate an absorption chiller, which is linked to the cogeneration unit, the trigeneration CHP can provide electricity heating and cooling for air conditioning.

Exhaust gas boiler is the high Efficient energy saving equipment for flue gas waste heat recovery of generator Sets.

1. Exhaust gas boiler is adopted pin heat transfer enhanced components, to Enlarge heat transfer area 6-8 times, improve the heat transfer coefficient 2 Times and increase the heat transfer efficiency 14 times.

2. Exhaust gas boiler has self-cleaning capability.

3. Exhaust gas boiler is less wear and tear, tightly sealed, less occupied Area,

About 20-50% of Industrial energy converted into waste. Waste heat recovery system provides and economical and emission free method to increase overall efficiency of the plants and, thus, to lower fuel demand.

- Reduce demand on primary energy

- Save natural resources by reduction of fuel demand

- Reduce CO2 emission

- Save cost over existing solution